Automatic Frying Process Machine System

Capacity: The system is designed based on the specific production needs of each unit, facility, business, or customer.

Yêu cầu báo giá

Thông tin sản phẩm

Automatic Frying Process and Benefits of Investing in a Frying Line

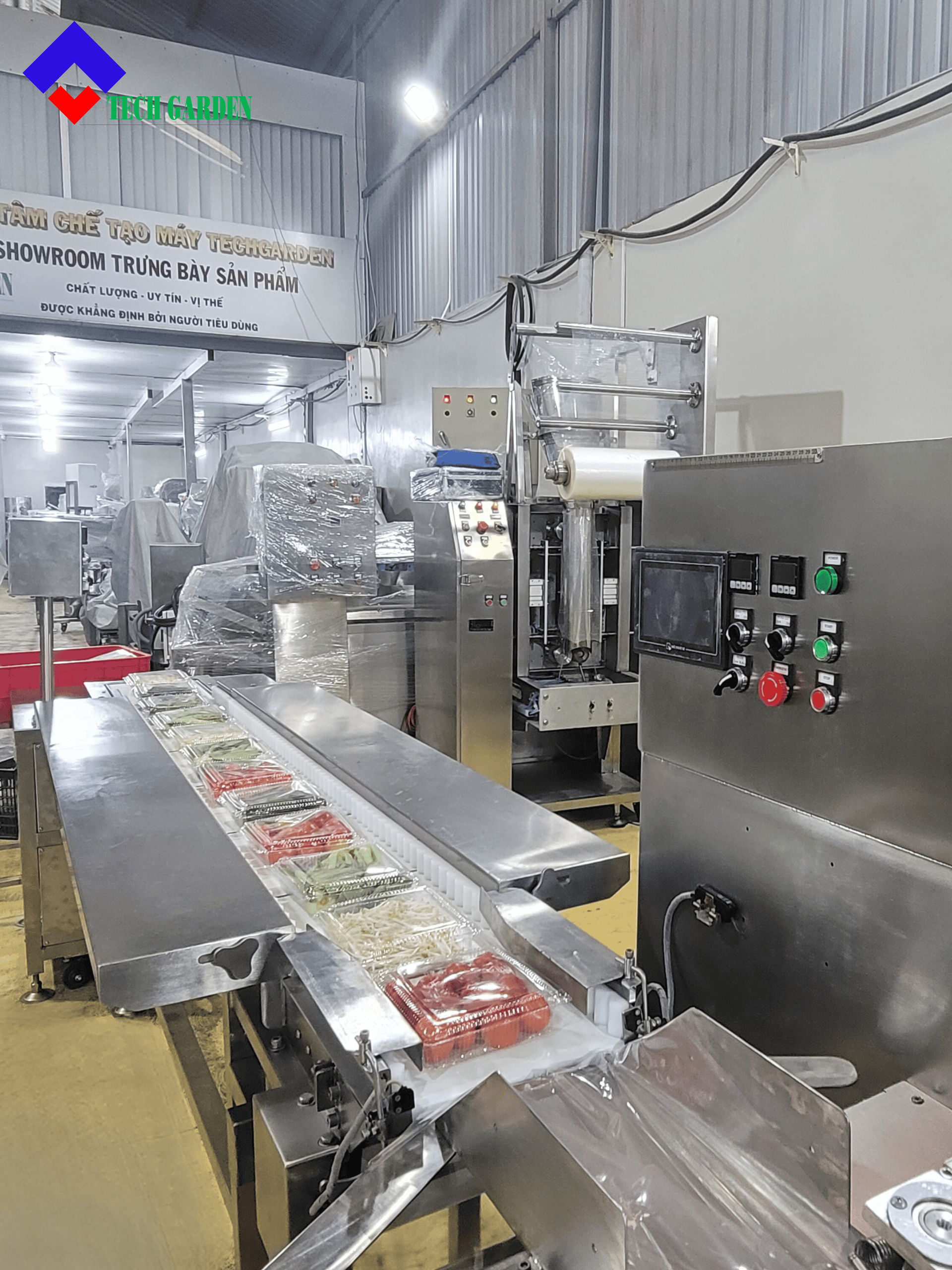

In the food industry, production follows specific processes to ensure high-quality products, and frying is one of the crucial steps in food processing. To enhance efficiency, many businesses have invested in automatic frying lines, including conveyor slicers, automatic frying machines, and centrifugal de-oiling machines from Tech Garden. This system ensures uniform quality, reduces operating costs, and optimizes the production process.

Image 1: Machine System in the Frying Process – Crispy Fried Banana Products

1. Automatic Frying Process Machine System

1.1. Conveyor Slicer

The conveyor slicer integrates two functions: material transportation and automatic cutting. Raw materials are fed into the machine, sliced into even pieces, and directly transferred to the fryer. This ensures uniform product size, improving the frying process efficiency.

Image 2: Conveyor Slicer – Slicing Bananas Before Frying

1.2. Automatic Frying Machine

The automatic frying machine precisely controls temperature and frying time. The rotating paddles ensure even cooking, maintaining crispiness and an appealing color. Additionally, an optional oil/filter tank helps maintain oil quality (depending on customer investment needs), reducing waste and ensuring food hygiene.

1.3. Centrifugal De-Oiling Machine

After frying, the centrifugal de-oiling machine removes excess oil using high-speed spinning force. This process ensures the product remains dry, stays crispy for longer, and maintains its quality.

2. Benefits of Using an Automatic Frying Line

2.1. Increased Productivity, Reduced Labor Costs

The automation system boosts production output without requiring excessive manual labor, minimizing errors and improving efficiency.

2.2. Consistent Quality Assurance

Automated control of key parameters ensures uniform size, color, and crispness of the product, reducing defects caused by human factors.

2.3. Savings on Raw Materials and Energy

Precise slicing reduces material waste. Effective temperature control optimizes oil and electricity usage, enhancing cost efficiency.

3. Convenience of Investing in an Automatic Frying Line

3.1. Easy Operation and Maintenance

The user-friendly interface makes operation straightforward. Quick-detachable components allow for hassle-free cleaning and maintenance.

3.2. Flexible Production Expansion

Businesses can adjust the production line according to demand, easily scaling up without replacing the entire system.

3.3. Maximized Profitability

By saving materials, reducing labor costs, and ensuring consistent product quality, businesses can maximize profits and gain a competitive edge.

The automatic frying line optimizes production, reduces costs, and guarantees product quality, making it the ideal investment for businesses aiming to enhance efficiency and meet market demands.

📌 Tech Garden specializes in designing, manufacturing, and distributing these machines nationwide.

📞 Contact 0935911775 – Mr. Tran Trinh for consultation.

📺 Watch more machine demonstration videos below: