Dried Rimmed Fish Packaging Line – Jar Feeding, Sealing, Capping, Labeling

Investing in a dried rimmed fish packaging line not only helps businesses increase productivity, optimize costs, and enhance brand value but also opens up export opportunities and ensures sustainable growth.

If you are looking for a professional packaging solution, this is the perfect choice! Tech Garden designs and manufactures machines tailored to the specific requirements of each company, business, and customer.

Thông tin sản phẩm

DRIED RIMMED FISH PACKAGING LINE – AN EFFICIENT AUTOMATION SOLUTION FOR BUSINESSES

Dried rimmed fish is a popular product on the market due to its delicious taste, convenience, and ease of storage. However, to enhance competitiveness, ensure food safety, and increase brand value, investing in an automated packaging line is essential.

The dried rimmed fish packaging line helps businesses increase productivity, reduce labor costs, ensure professional and consistent packaging, and meet export standards.

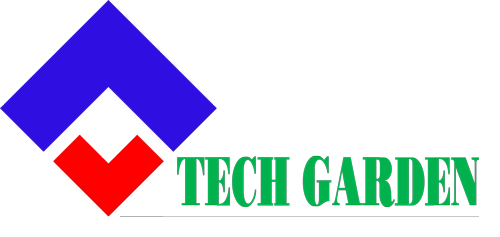

Image 1: Tech Garden’s technical team conducting a trial run of the dried rimmed fish jar packaging line.

Benefits of Using the Dried Rimmed Fish Packaging Line

✅ Increased Productivity – Reduced Labor Costs

The automated line shortens packaging time.

Only 1-2 operators are needed, minimizing labor costs.

✅ Ensured Food Safety and Hygiene

Minimizes product exposure to external environments.

Ensures hygiene standards, meeting both domestic and export market requirements.

✅ Optimized Production Costs

Reduces material waste and optimizes production expenses.

Saves packaging time, increasing business profitability.

✅ Enhanced Brand Value

More professional packaging attracts customers.

Meets high-end market demands, expanding distribution channels.

Structure of the Dried Rimmed Fish Packaging Line

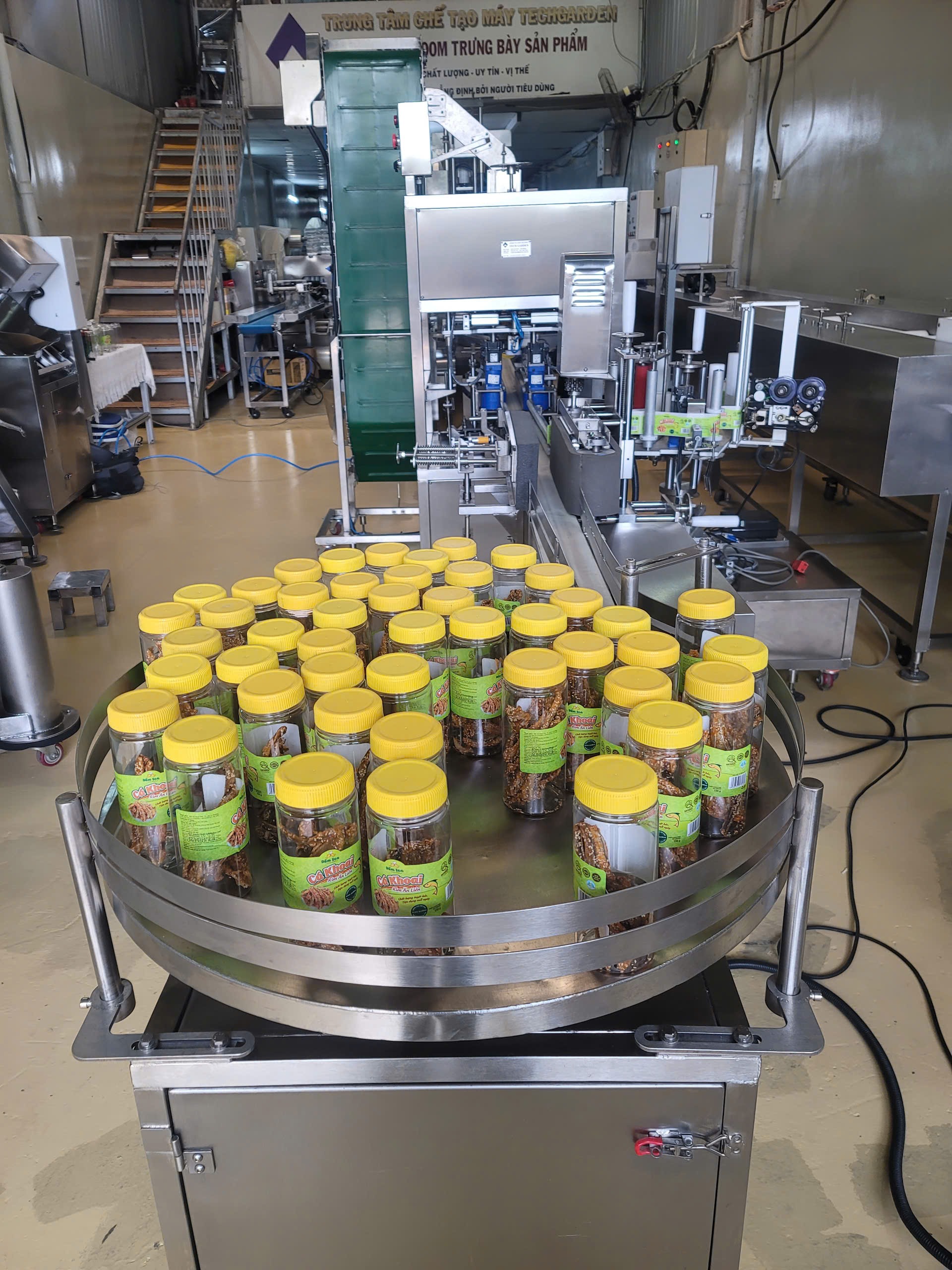

⭐ 2.1. Automatic Jar Feeding Rotary Table:

The rotary table automatically guides and directs jars onto the conveyor belt, leading them through the filling area.

- Function: Supplies jars at a preset frequency with high accuracy, reducing manual errors.

- Advantages: Continuous operation optimizes production time.

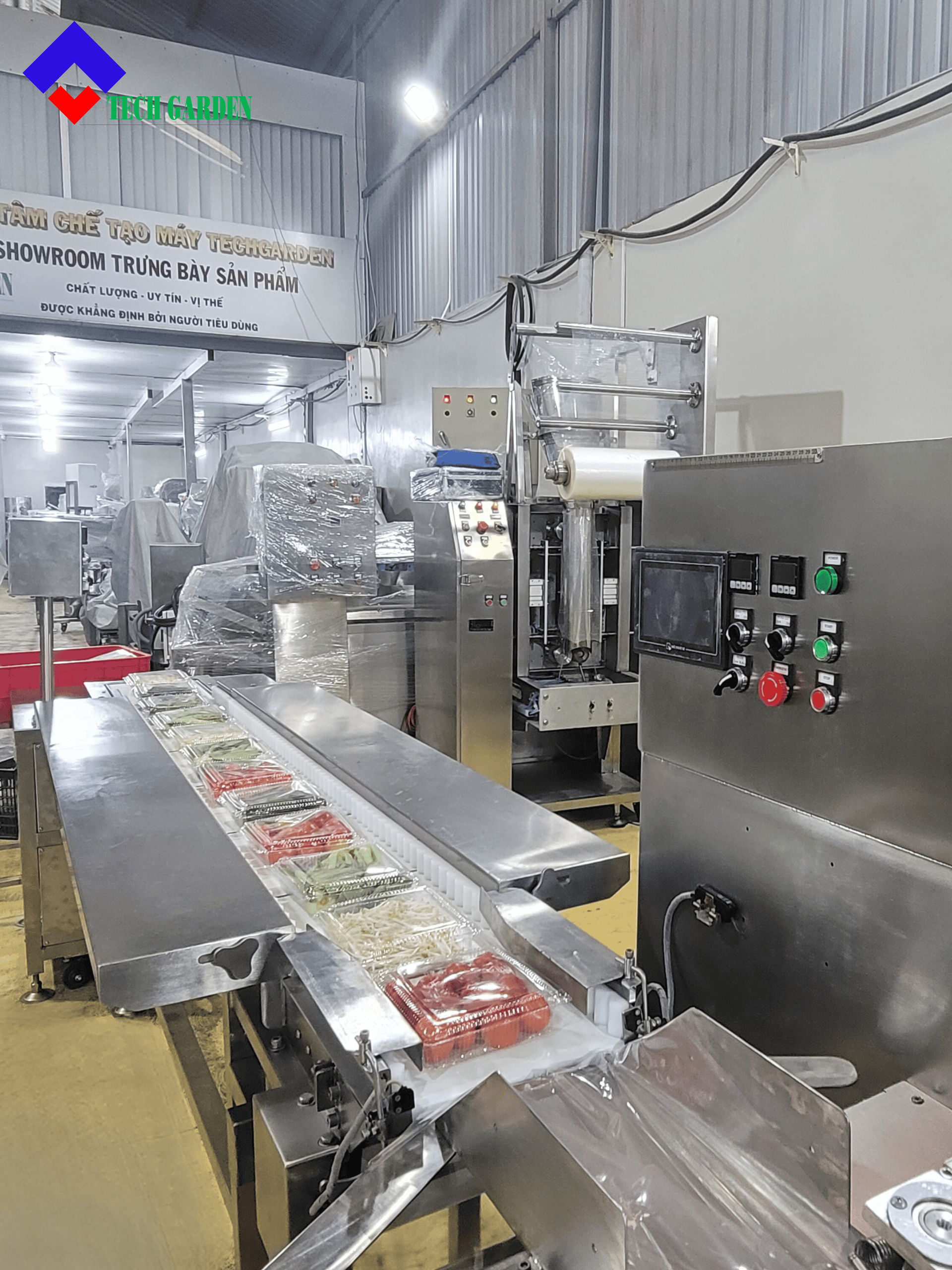

⭐ 2.2. Automatic Sealing Machine: Seal feeder, jar detection sensor, and heat sealing system.

- Function: Uses heat sealing technology to apply the protective seal.

- Advantages: Prevents air and bacteria from entering, extending shelf life.

⭐ 2.3. Automatic Capping Machine: Cap feeding system and capping unit with standardized torque control.

- Function: Ensures the cap is tightly secured, preventing leaks during transportation.

- Advantages: Supports various cap types, including plastic screw caps, aluminum caps, and flip-top caps.

⭐ 2.4. Automatic Labeling Machine: Label feeding system, label rolling unit, and position alignment sensor.

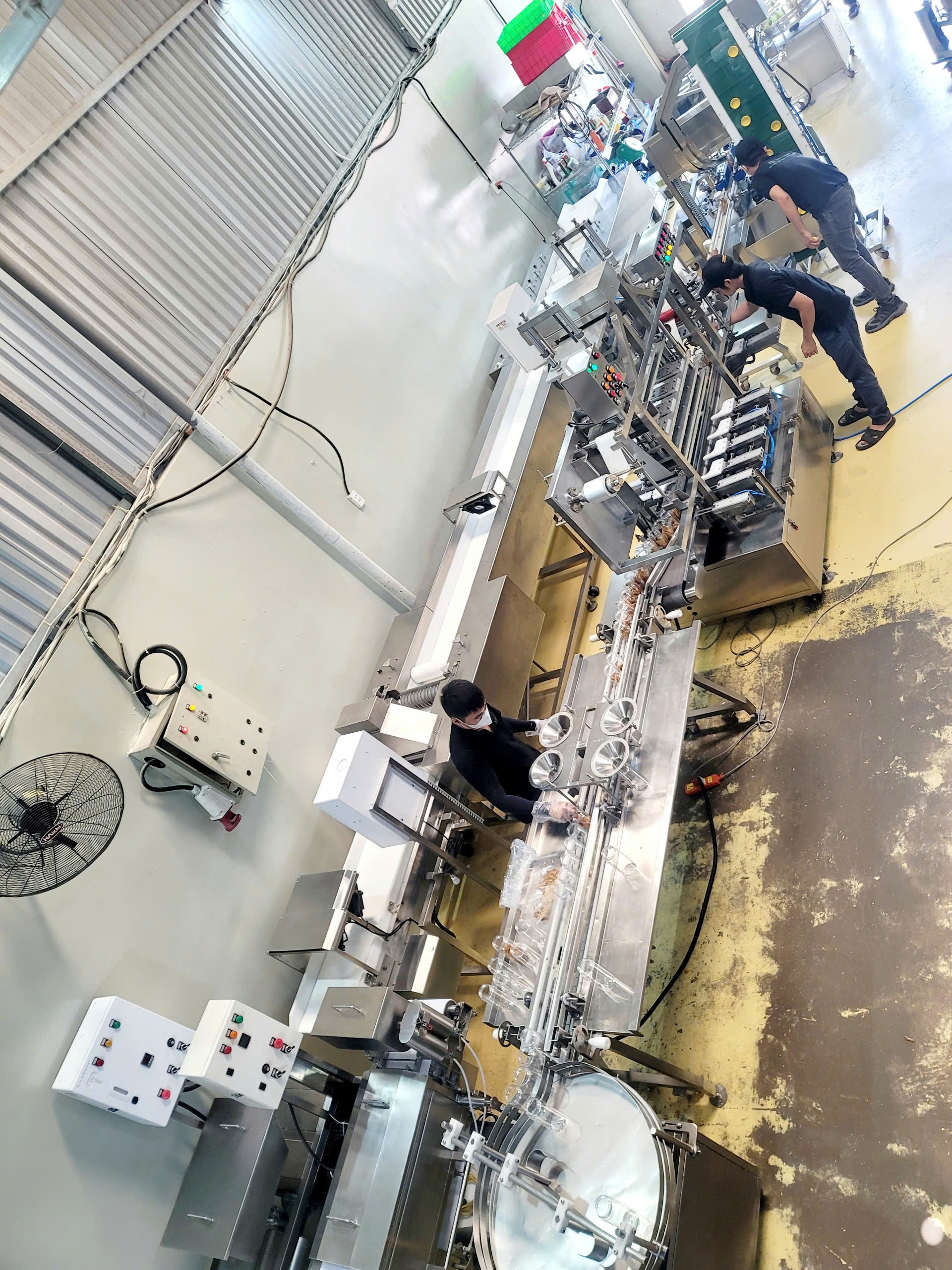

⭐ 2.5. Finished Product Rotary Table: The automatic rotary table directs product flow and assists in retrieving finished products from the labeling machine’s conveyor.

- Function: Retrieves finished products from the labeling machine’s conveyor.

- Advantages: Assists in collecting finished products, reducing bottlenecks when workers cannot keep up.

Potential of the Dried Rimmed Fish Packaging Line in Production

📈 Rising Market Demand

Consumers increasingly prefer pre-packaged, convenient, and safe food products.

The trend is shifting towards standardized packaged foods that are easy to store and transport.

🌍 Export Opportunities

Professional packaging allows businesses to enter supermarkets, convenience stores, and export markets with ease.

Meets the packaging standards of demanding markets such as the U.S., EU, and Japan.

💰 One-Time Investment – Long-Term Efficiency

High-durability machinery with easy maintenance helps businesses save long-term costs.

Enhances product value, increasing revenue and sustainable profits.

Tech Garden – A Trusted Packaging Line Provider

Tech Garden’s dried rimmed fish packaging machines are designed and manufactured to meet each customer’s specific requirements, ensuring suitability for all production scales.

🔹 Commitment to Quality

- Stable and durable operation.

- Advanced technology with energy-saving efficiency.

- Excellent warranty policies and 24/7 technical support.

The machines are designed, manufactured, and distributed nationwide by Tech Garden.

For consultation, please contact 0935911775 – M.Sc. Trần Trinh.

Check out the machine in the videos below: