Fresh Noodle & Noodle Production Line

🚀 Revolutionizing Fresh Noodle Production with Modern Technology

Fresh noodles—renowned for their delicious taste, soft texture, and quick preparation—are becoming an increasingly popular consumer trend. To meet the growing market demand, modern fresh noodle production lines have emerged, integrating advanced automation technology to enhance productivity, ensure consistent quality, and optimize production costs.

Thông tin sản phẩm

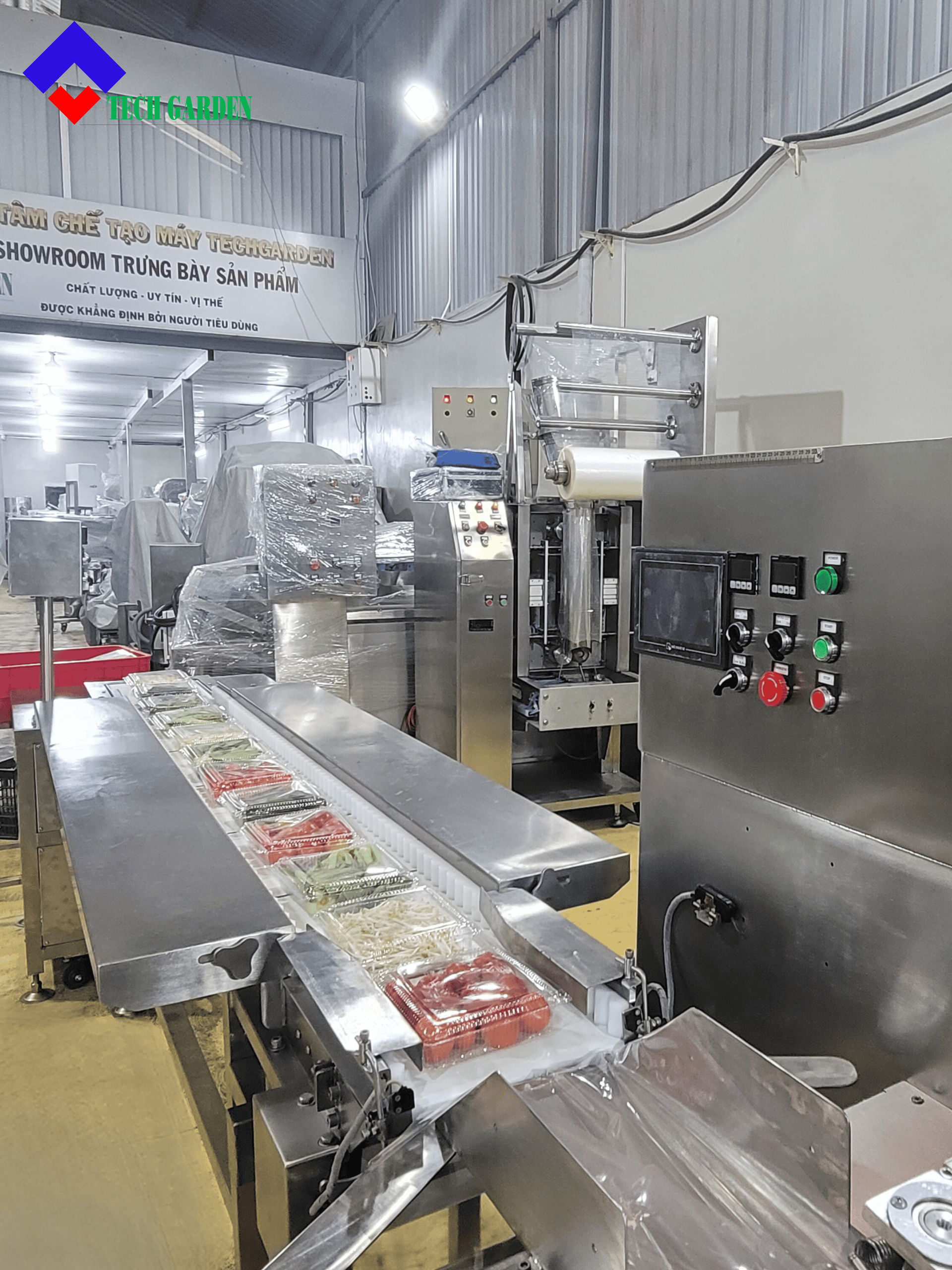

TECH GARDEN FRESH NOODLE & NOODLE PRODUCTION LINE

The food processing industry is rapidly evolving, continuously innovating to keep up with modern technology trends. As a result, automation and efficiency have become top priorities for food manufacturers. Understanding this demand, Tech Garden has launched a new product with outstanding functionality, designed to optimize production and enhance performance.

🔥 The Perfect Combination of the Fresh Noodle Production Line

With a wide variety of noodles, including fresh noodles, Udon, Ramen, and more, this system provides greater value and flexibility for food processing businesses. The fresh noodle production line consists of multiple interconnected machines, each designed with specialized features, ensuring a seamless and high-quality production process that meets the highest industry standards.

Figure 1: Fresh Noodle & Noodle Strand Production Line

The TECH GARDEN noodle production line is one of the most advanced machines, capable of producing noodle strands quickly and efficiently. Additionally, we can customize the machine based on customer requirements to align with the investment scale of production facilities.

💎 Outstanding Advantages of the Fresh Noodle Production Line

✅ High Automation: Minimizes manual labor and significantly increases productivity.

✅ Cost Savings: Reduces raw material and energy consumption, optimizing profitability.

✅ Stable Product Quality: Strict control at each stage ensures noodles meet quality standards.

✅ Food Safety & Hygiene: Made from stainless steel, easy to clean and maintain.

✅ Flexible Production: Easily adjusts noodle shape and size to meet diverse market demands.

Production Line Includes: Dough Mixer, Dough Sheeter, Noodle Cutting Machine, and Manual-Feeding Noodle Packaging Machine.

💡 1.1 Dough Mixer – The Foundation of Perfection

✔ Function: Mixes ingredients (flour, water, and additives) to ensure a consistent initial quality foundation.

✔ Key Features:

- Automatic Mixing System: Continuous blade rotation ensures even mixing without clumping.

- Adjustable Speed & Mixing Time: Can be customized based on recipes and product quality requirements.

- Stainless Steel Construction: Easy to clean and guarantees food safety.

Figure 2: Dough Mixer

🔄 1.2 Dough Rolling Machine – The Foundation Step

✔ Function: Rolls the mixed dough into

✔ Key Features:

- Adjustable rolling system to control dough thickness as required.

- Enhances dough texture, making it soft, smooth, and elastic for better noodle quality.

- Powerful motor ensures stable operation and increased production efficiency.

Figure 3: Dough Rolling Machine – Rolling Pre-Mixed Dough into Adjustable Thickness Sheets

🌀1.3 Dough Rolling & Cutting Machine – Precision in Every Noodle Strand

✔ Function: Rolls the dough sheet to the desired thinness and cuts it into uniform noodle strands using a specialized cutting mold designed for precise and consistent sizing.

✔ Key Features:

- Multi-stage rolling system ensures the dough reaches the perfect thinness.

- Durable, high-quality cutting molds provide smooth, non-sticky cuts.

- Adjustable noodle sizes (thin noodles, udon, soba, etc.) by changing the cutting mold.

- Continuous operation optimizes production speed.

Image 4: Multi-Function Dough Rolling & Noodle Cutting Machine – Versatile & Efficien

Image 5: Testing the Dough Rolling & Noodle Cutting Machine – Producing Fresh Noodles

📦 1.4 Semi-Automatic Packaging Machine – Convenient & Cost-Effective Solution

✔ Function: Supports the packaging of fresh noodles into bags, enhancing storage efficiency, ensuring hygiene, and facilitating transportation.

✔ Key Features:

- Cost-effective: Lower investment compared to a fully automatic packaging system.

- Operational flexibility: Easily adjustable, compatible with various packaging types.

- Food safety assurance: Minimizes product exposure to external environments.

- Increased packaging efficiency: Assists workers in quick operations, boosting productivity.

- Easy maintenance & repair: Simple system with easily replaceable components.

Image 6: Semi-Automatic Packaging Machine – Manual Ingredient Feeding

A modern fresh noodle production line not only enhances operational efficiency but also ensures superior product quality. With advanced machinery and full automation, this is the optimal solution for fresh noodle manufacturers to achieve sustainable growth and strong market competitiveness. Investing in a fresh noodle production line – A breakthrough step toward success!

The machine is designed, manufactured, and distributed nationwide by Tech Garden.

For consultation, please contact 0935911775 – M.Sc. Trần Trinh.

📺 Watch product videos: